Products

Products

Materials

- Additives

- Alkaline dust

- Aluminium scrap

- Ammoniac nitrate

- Ammonium sulphate

- Amorphus coal

- Animal meal

- Ashes

- Ashes from clinker and cement

- Ashes/waste incin. plant

- Baked gypsum (cotto)

- Bauxite

- Biomass dust

- Black coal

- Blende

- Boiler ash

- Bran cement (crusca)

- Brown coal ashes

- Bypass dust

- Calcareus sand

- Calcium carbonate

- Calcium hydrate

- Calcium oxide

- Cement

- Cement and clinker dust

- Cement and lime

- Cement dust

- Cement meal

- Chemical product

- Clinker

- Clinker dust

- Coal

- Coal ashes

- Coal dust

- Conditioned ore - dryer dust

- Cooked gypsum

- Crushed limestone

- D.r.i.

- Dehydrate sludge (fanghi)

- Dolomite

- Dried chalk (gesso)

- Dry additives

- Dust

- Electrofilter dust

- Fertilizers

- Filler

- Filter dust

- Glass

- Gypsum

- Iron ore

- Iron oxide

- Lime

- Limestone

- Marble

- Marl

- Mineral salt

- Mortar premixed

- Naturgips

- Ore

- Pozzolan

- Pulverized coal

- Quicklime

- Raw mill

- Sand

- Slag

- Urban waste

- Wooden chips

- Zinc dust

- Zinc oxide

Drag chain conveyors

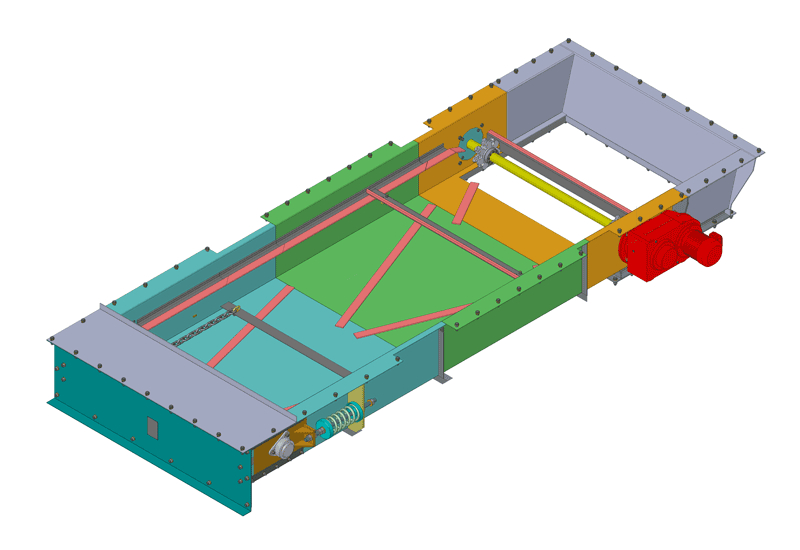

In several industrial sectors, the need for conveying free flowing bulk material of any type, in sealed and dust-proof environments, can be satisfied by the various types of drag chain conveyors designed and manufactured by Gambarotta Gschwendt.

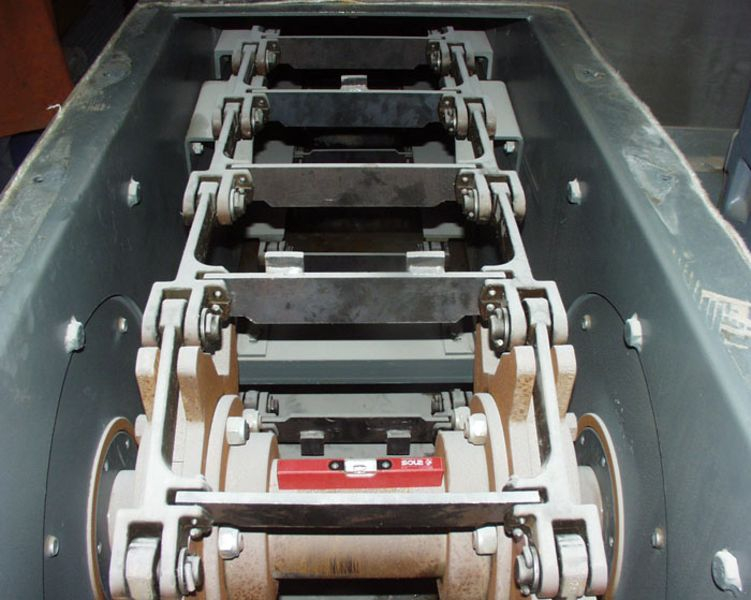

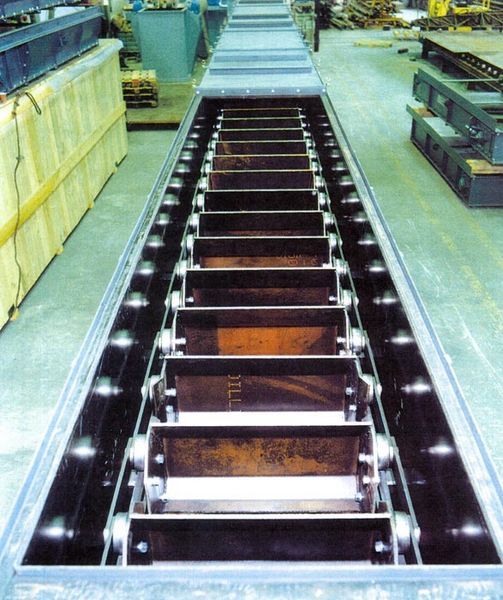

In these machines, material is conveyed by drag chains that move along the machine’s casing: the latter comprises a steel box with rectangular cross-section and hermetically sealed cover.

The toothed wheels of the drive station drive the chains fitted with appropriate scrapers; in turn, the chains drag a layer of material that, in some conveyor models, may be taller than the scarpers themselves. This occurs because the lower layer of the material, which is dragged directly by the scrapers, supports and conveys the upper layers to form a continuous flow of material travelling at the same speed as the chain.

This type of conveyor is highly appreciated for its ecological qualities in that it is completely closed; on the other hand, significantly high levels of installed power are required to contrast the scraping friction that is generated. Our product range includes several types of drag conveyors:

TRS - Drag chain conveyor with single drop forged chain: suitable for hauling fine-grained or small-sized material and relatively small capacities with any inclination (even up to 90°).

TRD - Drag chain conveyor with double drop forged chain: suitable for hauling lumps and medium-large capacities, generally with inclination < 20°.

TRA - Drag chain conveyor with double round steel chain: suitable for the same uses as the TRD, with the added advantage of having a lower vertical extension.

TRP - Scraper-paddle conveyor with double chain with rollers: suitable for the same uses as the TRD, but can be operated at high speeds (0.7 m/sec) thanks to the mobile parts supported by the chain rollers that roll on guides.

TRC - Submerged drag chain conveyor: suitable for recovering slag and ash immersed in water as a result of various industrial processes (e.g. extinguishing of boiler ash).

TRL - Cleaning drag chain conveyor with linear axis: suitable for recovering dust beneath main conveyors such as pan or belt conveyors.

TRLC - Cleaning drag chain conveyor with curved axis: suitable for recovering dust beneath main conveyors and recycling them on the latter.

Gambarotta Gschwendt is able to revamp, modify and enhance drag chain conveyors of any manufacturer and solve any problem regarding handling of continuous flowing bulk material. Moreover, the company is able to supply any spare part for lifting and hauling machines.