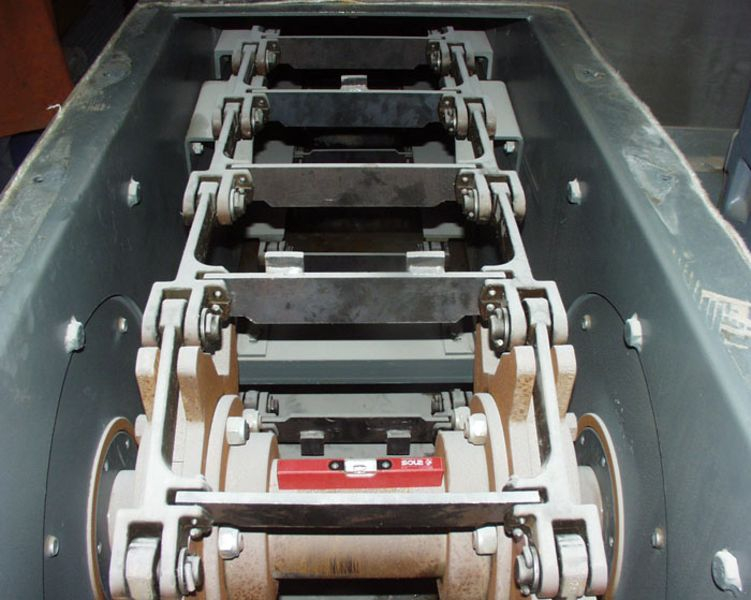

TRD - Drag chain conveyor with double chain

Description:Drag chain conveyors equipped with two drop forged chains that drive the material: the chains are made of wear-resistant steel and include side connecting ribs for linking the scrapers located between the two rows of chains. The machine may also haul medium-large-sized materials. The scrapers, generally in the form of a plain flat profile, are equipped with a rear stiffening on larger-sized conveyors.These conveyors mount traditional spring-type or hydraulic chain tensioning systems that are located in the return station.

Functional specifications:

Functional specifications:

- Recommended speed: below 0.40 m/s depending on material abrasiveness.

- Preferably linear hauling, although wide-radius curves can be included on the vertical plane.

- The inclination should preferably be kept below 20°.

- Material may be hauled on both upper or lower runs.

- Multiple material feed and discharge points may be located along the conveyor; intermediate discharge points are equipped with a slide gate.

- Inlets fitted with an intermediate partition panel may be used for extracting material: the partition panel must be placed below the inlet, between the upper and lower sections of the conveyor chain, and supports the pile of material to be extracted.

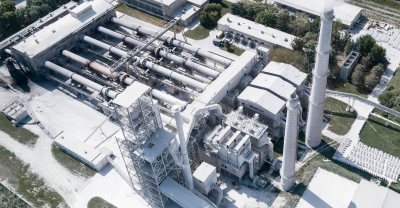

trd

Related materials

- Additives

- Bauxite

- Black coal

- Blende

- Boiler ash

- Bran cement (crusca)

- Brown coal ashes

- Bypass dust

- Calcareus sand

- Calcium carbonate

- Calcium hydrate

- Calcium oxide

- Cement

- Cement and clinker dust

- Cement and lime

- Cement dust

- Cement meal

- Chemical product

- Clinker

- Clinker dust

- Coal

- Coal ashes

- Coal dust

- Conditioned ore - dryer dust

- Cooked gypsum

- Crushed limestone

- D.r.i.

- Dehydrate sludge (fanghi)

- Dolomite

- Dried chalk (gesso)

- Dry additives

- Electrofilter dust

- Fertilizers

- Filler

- Filter dust

- Glass

- Gypsum

- Iron ore

- Iron oxide

- Lime

- Limestone

- Marble

- Marl

- Mineral salt

- Mortar premixed

- Naturgips

- Ore

- Pozzolan

- Pulverized coal

- Quicklime

- Raw mill

- Sand

- Slag

- Urban waste

- Wooden chips