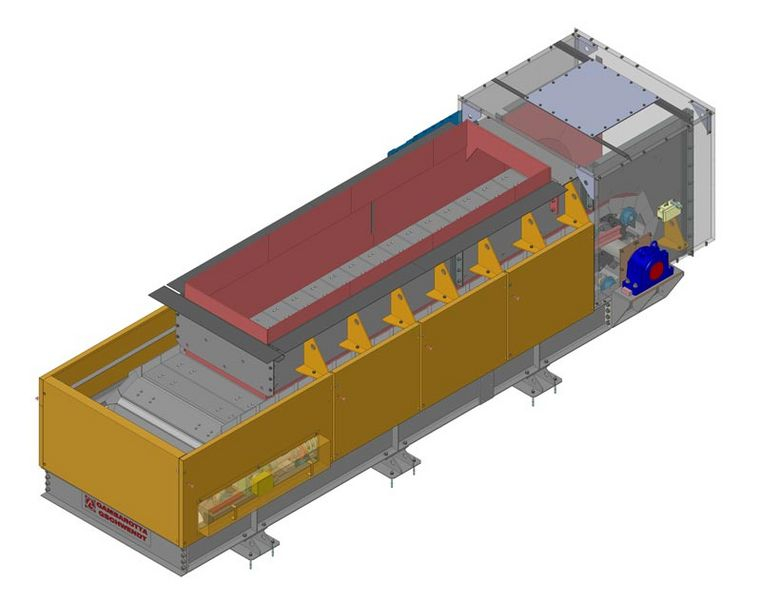

EP - Apron feeders

Description:Used for extracting bulk material (clinker, limestone, gypsum, coal, minerals, etc.) in lumps of up to 500 mm from hoppers or silos. These machines are generally linear-shaped and placed horizontally, although they may rarely be used with a slightly inclination (up to about 20°).The extractors comprise a sturdy electro-welded structure that supports the metal deck conveying the material. This deck is formed by a series of base pans - sometimes equipped with reinforced supports on the lower section - joined together by the drive chains. The rigidity of the pans is designed to withstand the static load that is thus distributed onto the side tracks through the support and guide rollers. In the intermediate section, the pans have one or more guide shoes that adhere to the corresponding intermediate tracks only in the event of large dynamic actions (when material falls on the metal deck). The pans have two small side walls that help to contain the material. A suitable lip placed between two successive plates prevents downward spillage of fine-grained material.Two Link chains with pins and fixed bushings, which are bolted under the pans, connect the various pans so as to form a continuous metal deck that is jointed thanks to the chain pins.Every second pan is equipped with a pair of rollers with guiding edge and rolling-element bearings: these roll on appropriate tracks and support the metal deck with its load of material.A rigid crossbar placed above the metal deck - in the area where the material exits the hopper or silo - helps to limit the height of the material being extracted. This component, together with the conveying speed (almost always adjustable), allows for achieving the desired flow rate. The drive station in the discharge zone includes a drive unit that imparts movement to the deck, while the return station on the opposite end includes the chain tensioning station.

- Recommended speed: < 0.20 m/sec with the possibility of adjustment to 1:6 reduction ratio or more.

- Rarely, a curve on the vertical plane may be required (recommended radius > 5 m).

ep

Related materials

- Aluminium scrap

- Amorphus coal

- Animal meal

- Baked gypsum (cotto)

- Bauxite

- Black coal

- Blende

- Calcium carbonate

- Clinker

- Coal

- Cooked gypsum

- Crushed limestone

- D.r.i.

- Dehydrate sludge (fanghi)

- Dolomite

- Dried chalk (gesso)

- Dry additives

- Glass

- Gypsum

- Iron ore

- Iron oxide

- Lime

- Limestone

- Marble

- Marl

- Mineral salt

- Naturgips

- Ore

- Pozzolan

- Quicklime

- Slag

- Urban waste

- Steel scrap

- Clay