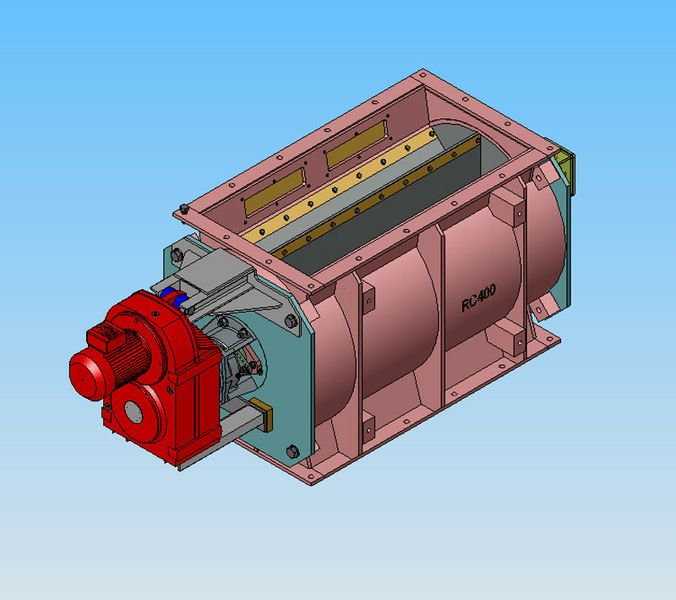

RC - Rotary valves

Description: Valves with a rotating chamber used to transfer a flow of fine solid material across two areas in which different pressure and/or temperatures are maintained. This valve can act as a feed valve (chamber feeders), extracting material from a hopper or silo and transferring it to the next machine. In this case for 100% filling, the material should be fine grade (powder).When this valve is used for unloading (chamber unloaders), it can accept granular or small lump material because filling is less than 100% and so there is less need to crush granules of materials passing through the rotor. Special rotary valves are used for coarser grade material.Our company has standardised 15 sizes with capacities of up to 500 mc/h. The cast iron versions of the five smallest (capacity up to 60 mc/h), are available from stock. The largest sizes are made in structural steel. Gambarotta also makes special versions with different sizes and functions, such as RC-A self-cleaning rotary valves, RC-G rotary valves for granular material and others such as cooled shaft valves for hot materials and valves in special steels. Construction characteristics:

- Outer casing with square or rectangular material intake and discharge points, two bolted side covers that support the adjustable triple packed gland seals and the rotor shaft supports with rolling element bearings.

- Rotor with five or more material chambers, complete with axial shaft.

- Standard control unit with hollow gearbox shaft keyed onto shaft with torque arm. Other types of control may be fitted.

- rotation control sensor.

rc

Related materials

- Additives

- Alkaline dust

- Ammoniac nitrate

- Ammonium sulphate

- Amorphus coal

- Animal meal

- Ashes

- Ashes from clinker and cement

- Ashes/waste incin. plant

- Baked gypsum (cotto)

- Biomass dust

- Boiler ash

- Bran cement (crusca)

- Brown coal ashes

- Bypass dust

- Calcareus sand

- Calcium carbonate

- Calcium hydrate

- Calcium oxide

- Cement

- Cement and clinker dust

- Cement and lime

- Cement dust

- Cement meal

- Chemical product

- Clinker dust

- Coal

- Coal ashes

- Coal dust

- Dehydrate sludge (fanghi)

- Dried chalk (gesso)

- Dry additives

- Dust

- Electrofilter dust

- Fertilizers

- Filler

- Filter dust

- Glass

- Gypsum

- Iron oxide

- Lime

- Limestone

- Marble

- Mineral salt

- Mortar premixed

- Naturgips

- Pulverized coal

- Quicklime

- Raw mill

- Sand

- Sugar

- Zinc dust

- Zinc oxide

- Pta