DV - Deviators

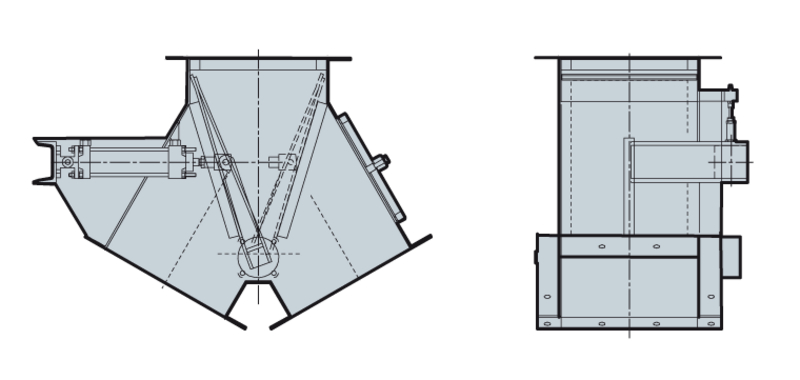

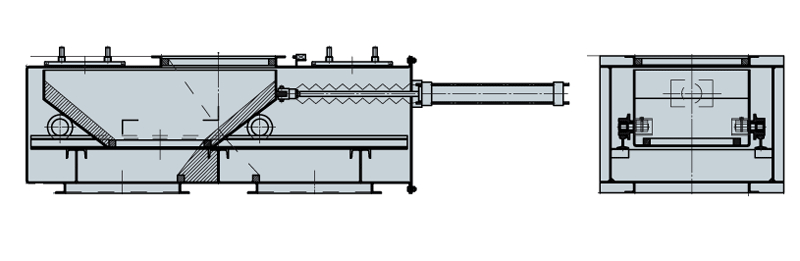

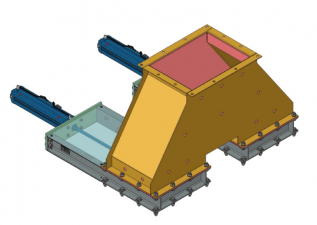

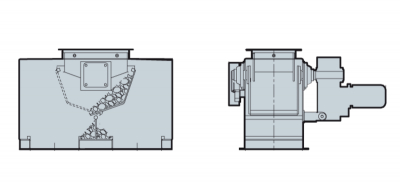

The purpose of deviators is to deviate the flow of solid material, fine-grade or in lumps, two or more ways. They have an intake point and two or more discharge points. They can be of various shapes, depending on the material to be handled and the inventiveness of the designer. The most commonly used deviators are the type DV two-way deviators shown below, suitable for generally fine or small-lump and not particularly abrasive materials.DV: two-way deviators with deviation gear and manual, pneumatic or motorised deviation system.DV with oscillating deviation blade

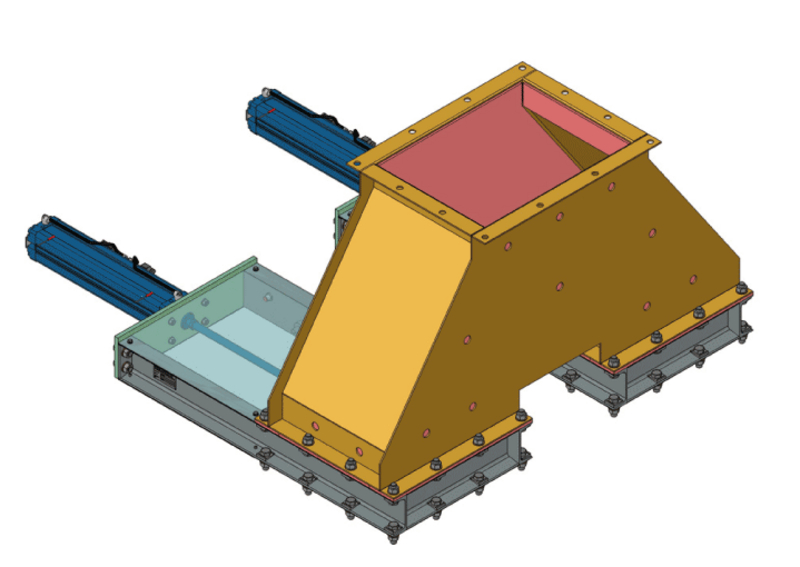

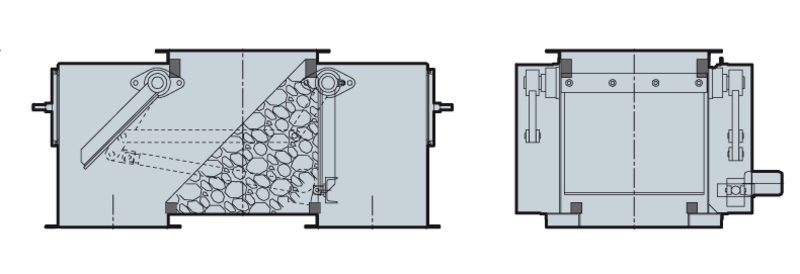

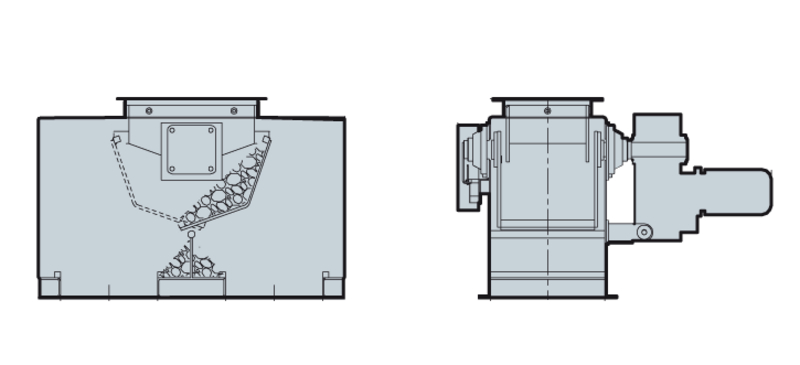

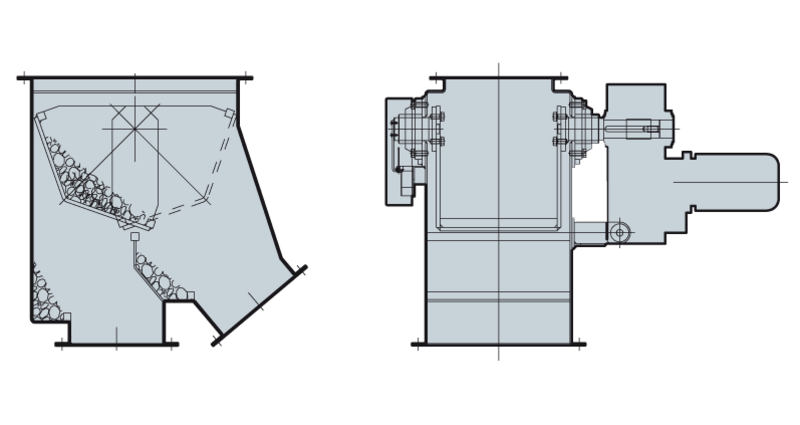

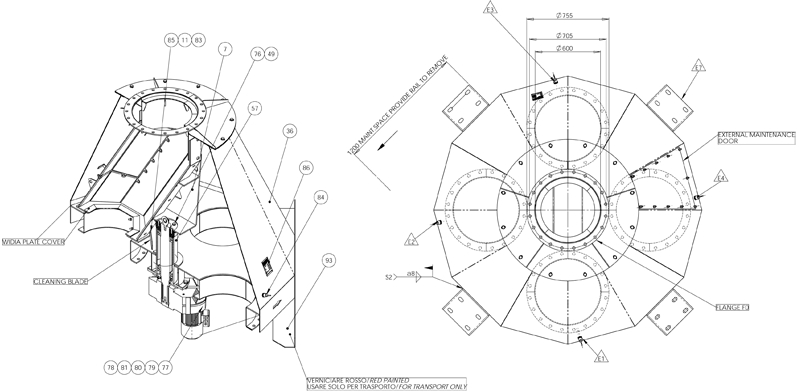

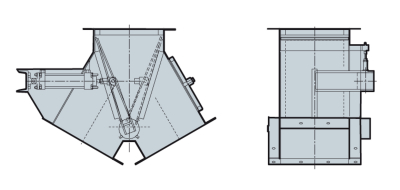

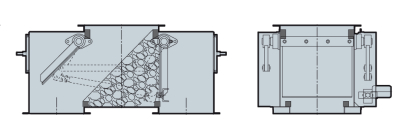

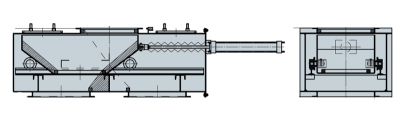

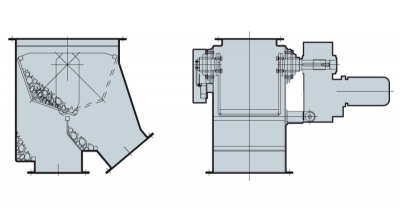

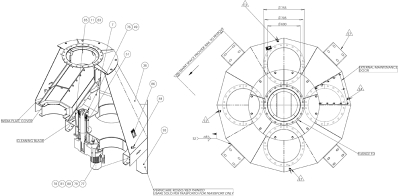

DV with deviation by SG guillotine slide gateDV-B: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points, deviation gears formed by a pair of oscillating walls (flags) operated by motorised or pneumatic cylinder.DV-C: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points. Deviation is achieved with a movable box on wheels with rail-guided bearings. Box drive unit with a pair of pneumatic cylinders.DV-E: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points. Deviation through an oscillating helmet. Helmet drive unit with gear motor or pneumatic cylinder.DV-R: Multiple way (3, 4, 5, 6 etc) rotary deviators for material in powder or lumps formed by a conical outer casing with upper intake point and “n” discharge points equally distributed around the periphery of the base of the cone. Deviation is achieved through slanted pipe work rotating around a vertical shaft to position on the selected outlet point. Gear motor drive unit.

DV with deviation by SG guillotine slide gateDV-B: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points, deviation gears formed by a pair of oscillating walls (flags) operated by motorised or pneumatic cylinder.DV-C: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points. Deviation is achieved with a movable box on wheels with rail-guided bearings. Box drive unit with a pair of pneumatic cylinders.DV-E: Two–way deviators for material in lumps (clinker, limestone, coal, etc.) consisting of an outer casing with an intake point and two discharge points. Deviation through an oscillating helmet. Helmet drive unit with gear motor or pneumatic cylinder.DV-R: Multiple way (3, 4, 5, 6 etc) rotary deviators for material in powder or lumps formed by a conical outer casing with upper intake point and “n” discharge points equally distributed around the periphery of the base of the cone. Deviation is achieved through slanted pipe work rotating around a vertical shaft to position on the selected outlet point. Gear motor drive unit.