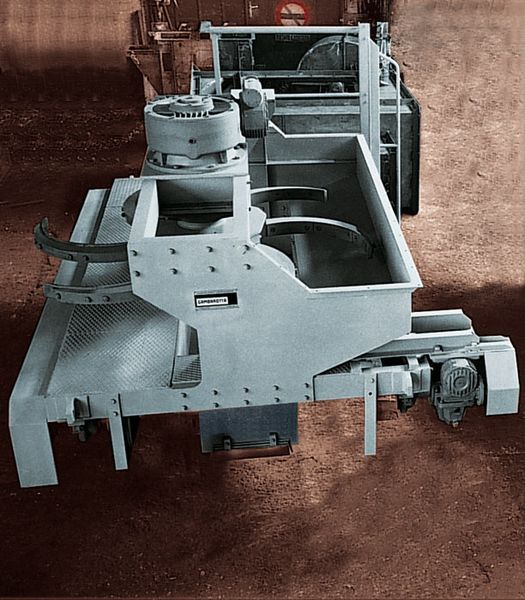

EF - Trailer-mounted milling extractors

Description: Used for extracting small to medium-sized bulk material (up to roughly 100 mm) such as coal, limestone, various minerals, etc. from longitudinal storage chambers with rectangular base. These extractors essentially consist of a motorised trailer that supports a vertical-axis extraction rotor equipped with a series of spiral-shaped arms (mill), with diameter between 2,000 and 4,000 mm or more.The outer parts of the arms skim the lower level of the storage chamber inlet. The latter comprises a longitudinal bracket that supports and stops the material above it and includes a vertical slit that can be adjusted height-wise. With their rotary movement, the arms extract the material from the vertical slit and shift it towards the mill axis where it is then discharged onto a belt conveyor placed beneath the milling extractor.The extraction rotor is driven by an electro-mechanical drive unit (motor and gear reducer) or hydraulic drive unit capable of imparting different speeds at a 1:10 reduction ratio and 2.5 m/sec maximum flow rate on the outer parts. The trailer generally mounts the same type of motor as the rotor.An extractor version with simultaneous extraction from two zones lying symmetrically to the mill axis can be constructed: this allows for doubling the flow rate, all other parameters being equal.The various possible configurations of the storage chamber bottoms sometimes require a customised shape for the trailer, which may come with incorporated mill or with the mill applied underneath the trailer.

ef