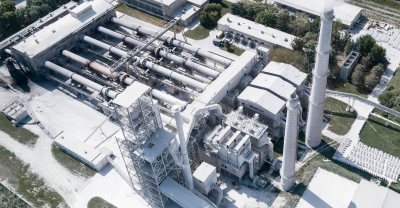

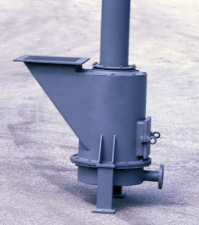

CV - Vertical screw conveyors

Description: These machines use a high-speed (400 – 600 rev./hour) full-bladed screw rotor to vertically lift fine-grained materials inside a tubular structure.The rotor, which is formed by a pipe equipped with wear-resistant steel full blades, comprises various sections each 3-4 m long: these are linked together by special intermediate supports made of sintered material given that they operate without any lubrication. The upper section includes end supports with rolling-element bearings and has a shaft protruding upwards that is driven by an electric motor and V-type belt transmission.To help trigger-off material lifting, the base includes an air-fluidified system.The following standard screw sizes (rotor diameter) are currently available: 160, 200, 250, 300 and 400. The lifting flow rate may reach 400 m3/hour for the largest screw, while material may be lifted to heights of up to 30-40 metres.The greatest advantage offered by vertical screw conveyors lies in their reduced surface bulk. For this reason, they can be used when modifying plants to save space, especially if they are only used occasionally.

cv

Related materials